There are 4 different types of noise generated by wind turbines: tonal, broadband, low frequency, and impulsive [3].

Tonal noise is discrete frequencies that are caused by meshing gears, non-aerodynamic instabilities and unstable flows over holes or the blunt trailing edge of the blade moving through the air.

Broadband is the “swishing” or “whooshing” sound greater than 100 Hz. Broadband disturbance is caused by atmospheric turbulence. Low frequency is 20 to 100 Hz from downwind turbines that cause localized flow deficiencies. Impulsive is short, thumping sounds due to disturbed air flow around the tower of the downwind turbine.

Wind turbine noise is created from two different general sources: mechanical and aerodynamic.

Mechanical Noise

Mechanical noise is from components such as the generator, auxiliary equipment (hydraulic systems), gearbox, yaw drives, cooling fans, and ducts [4]. The majority of the noise is from the gearbox or generator and is a form of structural noise that travels along and is amplified by the bearings, hub, rotor, nacelle, and tower. These noises are tonal and narrowband which are more irritating to humans than broadband.

The noise can be reduced from vibration suppression and damping, vibration isolation, and fault detection techniques for noisy gearboxes. Absorbers are an active method of noise suppression which incorporates sound isolating materials and insulating holes in the nacelle. A special finishing of gear teeth can reduce noise as well as utilizing low-speed cooling fans [3]. Components can also be mounted at the nacelle instead of ground level to reduce unwanted noise.

Aerodynamic Noise

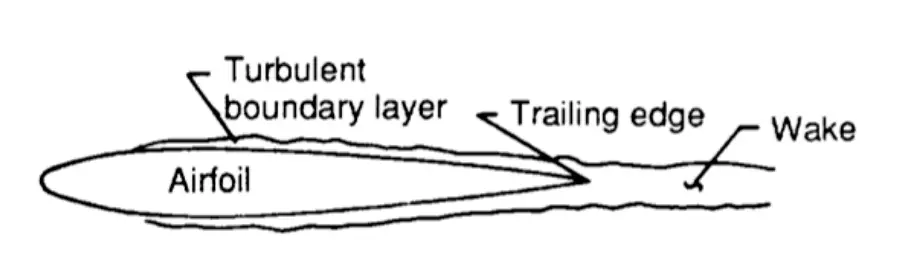

Aerodynamic noise is the dominant culprit of noise and also the most difficult to address. In total there are six areas of the blade that create noise: the turbulent boundary layer trailing edge, laminar boundary layer vortex shedding, separation stall, trailing edge bluntness vortex shedding, tip vortex formation, and turbulent inflow [4].

The majority of the noise occurs at the trailing edge of the blades due to turbulence. This “hissing” or “whooshing” sound is generated as the blade chops through the air turbulence and can be magnified if one turbine is placed in the wake of another in the same wind farm.

This noise can be reduced by increasing the pitch angle of the blades (and thus reducing the angle of attack) as well as lowering the rotational speed. These methods can significantly decrease the power output; however, so typically other methods are used. It should be noted that at high wind velocities, the sound of the wind actually masks the noise of the turbine. The surface finish of the airfoil also affects the noise levels, which occurs on both the suction and pressure sides of the airfoill. Optimizing the airfoil is a top tactic at reducing noise. Lower tip speed ratios reduces noise as well as incorporating modified blade trailing edges [3].

Separation-stall noise is caused when the angle of attack is increased [4]. This adds to the boundary layer on the suction side which magnifies the sound by 10 dB on average. For small separation, the noise is located from the trailing edge and for large separation (deep stall) from the chord. Laminar boundary layer vortex shedding causes noise from the feedback loops between the trailing edge and instability waves, also known as the Tolmein-Schlichtin waves.

The pressure waves are caused by vortex shedding propagating upstream from the trailing edge. The tip vortex formation noise is due to the interaction of the viscous turbulent core tip vortex and the trailing edge near the tip. The trailing edge bluntness vortex shedding noise is caused by the vortex shedding from blunt trailing edges and are dependent on the thickness of the trailing edge and proportional to the sixth power of the velocity. Turbulent inflow noise is amplified at low frequencies.

Older wind turbines, from the 1980s, would make a “hum” or “whine” from the mechanical components or unusual wind currents and could be heard from a mile away (and most likely to this day still gives wind turbines a bad reputation) [5]. Compared to an industrial or manufacturing plant, wind farms are actually very quiet. The main difference is wind plants tend to be located in rural areas where there is not much background noise (besides the wind) to drown out the sound. If the wind farm is located in the hills, the turbine noise can travel further by echoing in comparison to a flat terrain. Modern wind turbines actually have the same noise level as a household refrigerator from a distance of 750 feet. One can stand underneath a wind turbine and have a normal conversation without having to raise one’s voice.

How is Wind Turbine Noise Decreased?

Manufacturers have decreased the noise of wind turbines in various ways. Firstly, there are less moving parts in modern wind turbine design in comparison to the 1980s.

Most rotors are facing upwind so that the rotor faces directly into the wind, reducing the “thumping” sound of downwind rotors. The shapes of the towers and nacelles are aerodynamically streamlined to reduce the noise of the wind passing through the turbine.

Vibration has also been dampened and reduced. The nacelles are soundproofed to reduce the noise of the generator, gears, and other moving parts. As wind turbine blades are designed to be more efficient, less aerodynamic noise is created. Gearboxes, one of the noisiest components, are designed to be quiet by flexing and thus reducing noise.

Paradoxically, small house-hold wind turbines (less than 30 kW capacity) are much noisier than large industrial size wind turbines. This is due to the fact that rotational speeds of smaller wind turbines are higher. Also, much less government money has been invested into the design of small wind turbines. These small wind turbines do not have controls to limit the rotor tip speed in high winds, which creates significant noise [3]. They are also more likely to be located near residential areas so the noise is greater due to their closer proximity to houses.

Biomimetic solutions (inspired by nature) are being implemented to reduce the noise of wind turbines. One such idea is using the wing design of the silent-flying owl which uses serrated feathers to minimize noise [5]. These owls are virtually undetectable until about three feet away – an amazing feat of stealth [6]. To adapt this design to wind turbine blades, the design can be more flexible, porous, and soft. These changes can reduce noise by up to ten decibels.

Final Thoughts

The sound of wind turbines is regulated and has standards established by the American Wind Energy Association (AWEA) and International Electrotechnical Commission (IEC) [3]. Wind turbine manufacturers must provide the sound power level measurement for a variety of wind speeds, which is confirmed by certified testing agencies. Upper noise levels are established for both daytime and nighttime as well as location type (i.e. commercial, mixed, residential, and rural).

In the United States, there is no federal noise regulation; however, the Environmental Protection Agency (EPA) has established noise guidelines. Local governments also have noise pollution regulations listed as a form of air pollution that cannot be greater than 10 decibels over the ambient baseline level (the average sound present 90% of the time).

Typically, wind turbines must adhere to 40 decibels maximum. Some wind projects have set up noise complaint resolution processes in which a phone number is provided for any public noise concerns [5]. Typically, there is a minimum distance or setback required between the wind farm and the nearest residence (usually 300 meters at 45 decibels, less noisy than an air conditioner) to prevent disturbances [7].