Water harvesting, or rainwater harvesting as it is also known, means collecting rain water from surfaces that it lands on, and channelling it into a storage device so it can be used at a later time.

Whilst the various systems for achieving this vary in their design, they all achieve the same purpose: to allow reclaimed rainwater to be used in place of water drawn from the water mains, thereby reducing the demand on water mains.

Harvested rainwater is described as non-potable. This means that the water that has been collected and stored is not safe for humans to drink, although sometimes harvested rainwater is used for livestock to drink, as we shall see later.

All water harvesting systems can be put into one of two categories – gravity fed or pumped.

Table of Contents

Types of Water Harvesting Mechanisms

Here are some examples of different types of water harvesting systems:

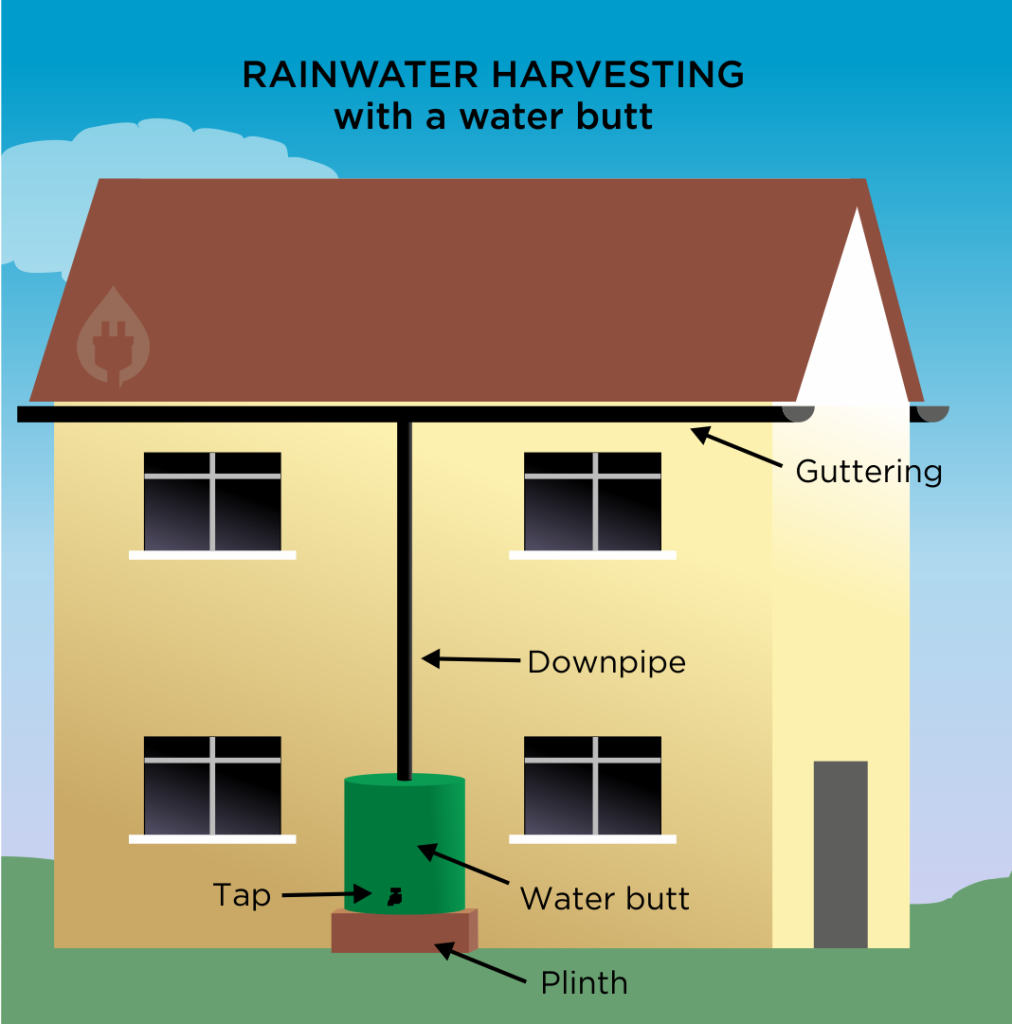

1. Water Butt

This is the most basic kind of water harvesting. A water butt is a large, usually cylindrical container that is placed underneath the downpipe of roof guttering. Rain falls onto the pitched roof and drains into the guttering, from where it runs into the butt and is stored.

The butt is raised on a plinth so that buckets, watering cans etc. can be placed under the tap and water drawn from the butt. This simple arrangement is a very common type of water harvesting, and is used in many domestic situations to provide water for gardening purposes. For domestic uses like this, water butts are usually made of hard plastic, and range in volume from around 50 litres (approx. 11 gallons) up to around 1000 litres (approx. 220 gallons).

The water butt is an example of a gravity-fed system – water flows down from the roof, through the gutters and pipes into the butt under the pull of gravity, and when the tap on the butt is turned, gravity pulls the water down out of the butt and into the bucket or watering can. Therefore no power is needed to pump the water at any time.

2. Retention Ponds

A retention pond, or retention basin as they are sometimes known, looks a lot like a normal pond. Rather than being naturally occurring, they are dug in specific locations, primarily for storm water management, and collect surface water run off from surrounding roads, paths, etc.

The quality of the water in the pond is improved by natural processes, e.g., solar disinfection, phytoplankton in the water that absorbs soluble pollutants, and sedimentation which allows solids to settle out of the water.

Retention ponds normally have a mud bottom, but in some cases are lined with concrete. The water from a retention pond can be used for watering livestock, irrigation, or any other non-potable use.

No pumping is required to transport water to the retention ponds, but depending on how the water is drawn from the pond for use, a pump may be required.

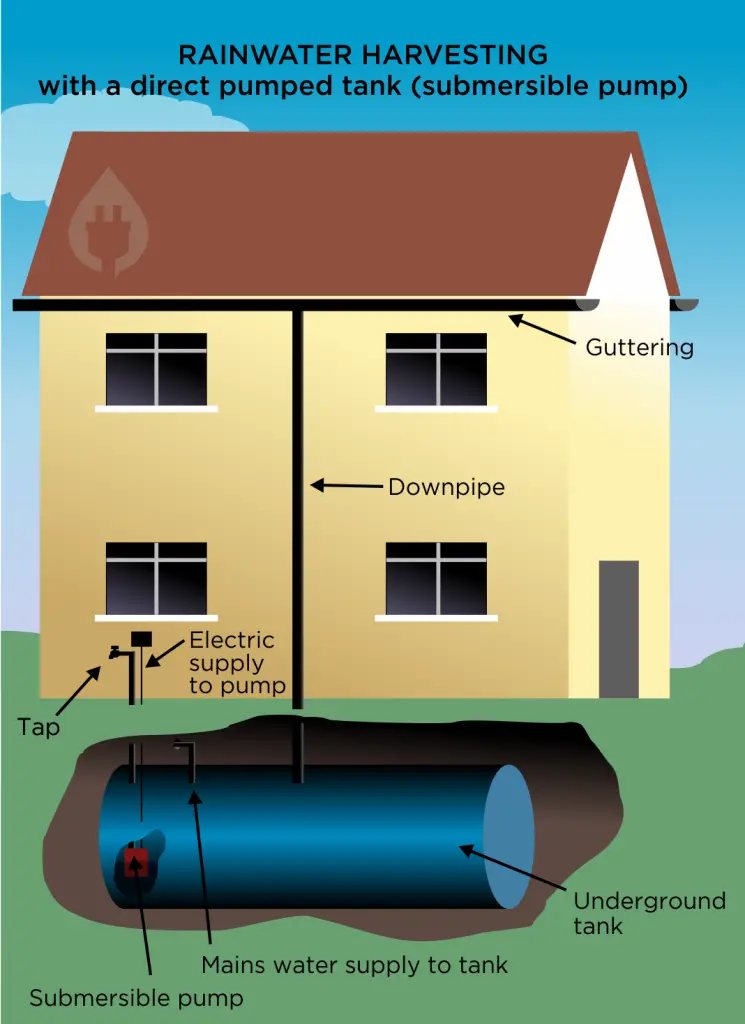

3. Direct-pumped Tanks

Large tanks (installed either underground or at surface level) are gravity-fed harvested water via standard rainwater collection systems (rooftop guttering, pipes etc). Then, when water is required, it is pumped up out of the tank to the tap where it is required.

Underground tanks are preferable to surface tanks, since they are installed below the frost line, which means the water in the tank doesn’t freeze if the external temperature drops below 0° Celsius. Underground tanks also have much better insulation against external high temperatures, which means that they exhibit a very low rate of evaporation in warmer weather.

The size of tanks used for these kind of installations ranges from 1000 litres (approx. 220 gallons) up to about 22,000 litres (approx. 4840 gallons). Direct-pumped tanks are fitted with filters and can be used for various non-potable water requirements, for example flush water for WCs, or domestic appliances such as washing machines.

The pump for a direct-pumped tank can be fitted either (a) within the tank itself (submersible direct-pumped system) or (b) outside the tank in a separate control unit (suction direct-pumped).

3a. Submersible Direct Pumped System

With the pump inside the actual tank, an electricity supply also has to be fed into the tank to power the pump. Note that with a submersible direct pumped system, a mains water feed is also supplied to the tank to prevent it running dry and ensure continuity of supply for appliances etc.

3b. Suction Direct Pumped System

With the pump outside the tank, this means no electricity supply needs to be fed into the tank, and the external pump (housed usually in a utility room or suchlike for ease of access for maintenance) sucks the water from the tank.

Suction pumps can be added to existing water tank systems, but for new installations, submersible pumps are more commonly used as they are generally more efficient.

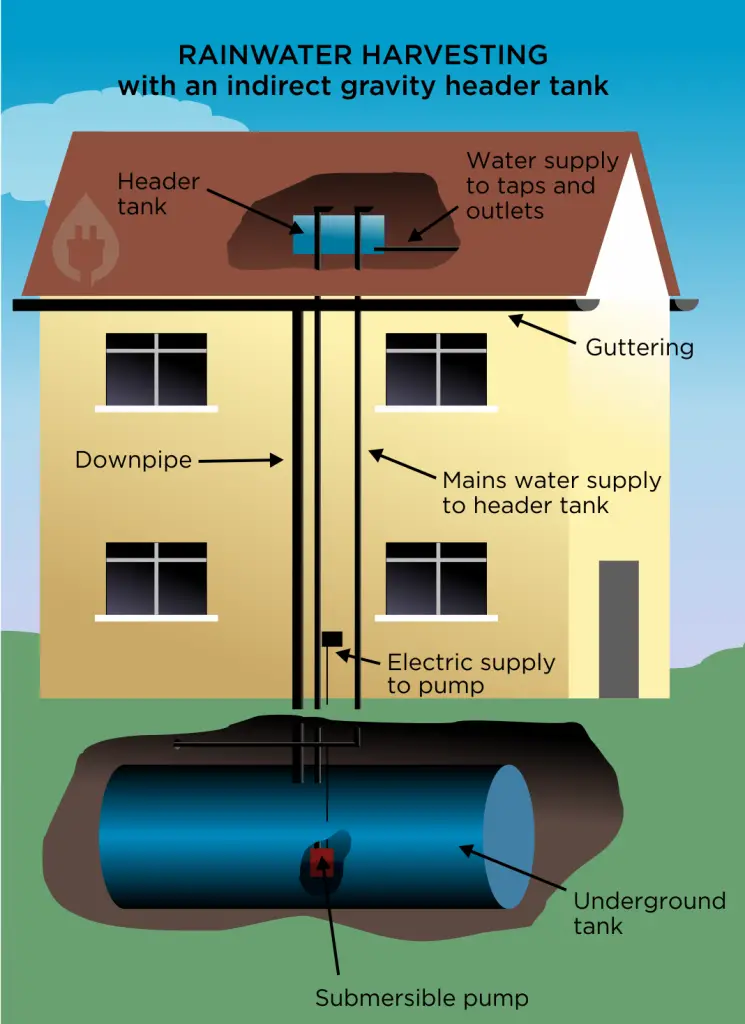

4. Indirect Gravity

With an indirect gravity system, the water is supplied to the taps by gravity alone. This requires the addition of another, smaller tank called a header tank that is situated in the highest point of the building. Harvested rainwater is still collected by gravity into a large storage tank (underground or surface level, same as a direct-pumped tank) but it is then pumped up to the header tank until the header tank is full. Then, when a tap is opened, gravity feeds the water from the header tank down to the tap, and a valve detects that the header tank is emptying and the pump refills it from the main storage tank.

With an indirect gravity system, the mains water feed is supplied to the header tank rather than the main storage tank. If the main storage tank runs dry, mains water is used to keep the header tank topped up until the main tank is refilled with harvested rainwater.

5. Indirect Pumped

An indirect pumped system is very similar to the indirect gravity system, in that it uses a main storage tank, and an additional smaller tank within the building. Where it differs is that the smaller tank does not have to be at the highest point in the building, it can be anywhere in the property, because a secondary pump is used to pump the water from the smaller tank to the tap / outlet where water is being drawn.

One of the advantages of indirect pumped systems is that the water pressure and flow rate from the taps can be adjusted by increasing or decreasing the power of the secondary pump, whereas with indirect gravity systems, the flow rate of the water is fixed by how much higher the header tank is above the tap where the water is being drawn from.

6. Gravity Only

Gravity only systems are only appropriate in a few situations, because it relies on situating the main storage tank high up above the taps / water outlets in the building and yet below the guttering / collection system.

Gravity alone can then feed water from the guttering into the storage tank, which is effectively then its own header tank. Then gravity again feeds the water from the storage tank down to the building where water is required.

The main advantage of this system is that it has no pumps and therefore requires no external power supply.